Our heat staking, inserting and thermal assembly systems are manufactured with the highest level of quality and concern for your application.

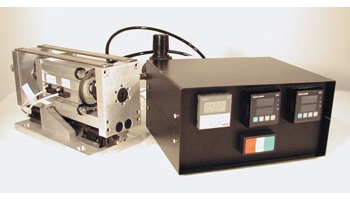

Toman ThermoSonics is the industry leader in design and manufacturing of single and multi-tipped heat staking equipment utilized in thermoplastic assemblies. From manual to fully automated heat staking systems, Toman offers complete solutions in heat staking, heat sealing, swaging, degating, embossing, date coding, decorating and inserting applications.

Toman ThermoSonics manufactures table top heat staking machines and completely automated heat staking systems, solving your thermoplastic assembly manufacturing problems. Toman designs and manufactures large multi-tooled heat staking machines with multiple heat stake tips for simultaneous processing. Toman’s heat staking equipment also offers custom designs with PLC capability for complete control and adjustments, rotary tables and slides to complete multiple assemblies.

Explore our heat staking products below, contact Toman with questions, or request a quote today: