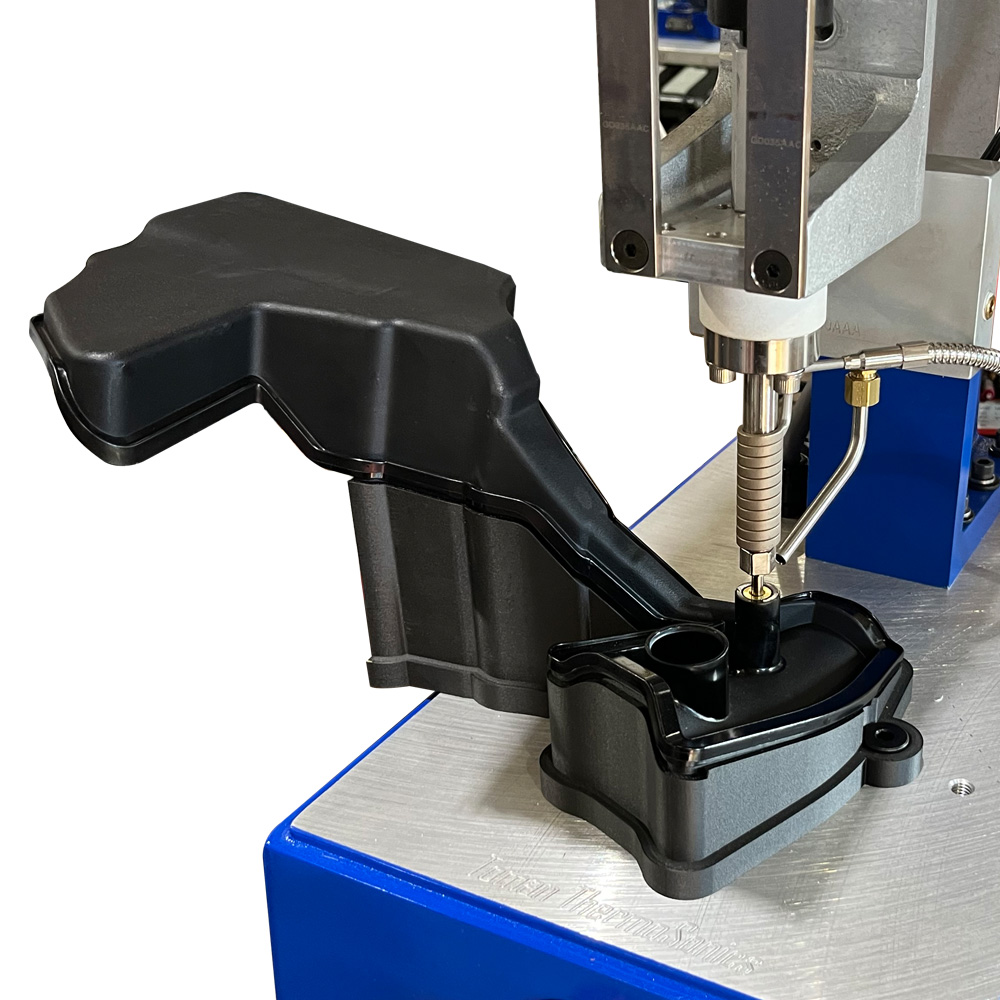

As a 3D Printing and Additive Manufacturing provider, we offer unparalleled value to manufacturers through innovation, efficiency, and customization. By leveraging cutting-edge additive manufacturing technologies, we help companies streamline their production processes, reduce material waste, and accelerate product development cycles. We have the capability to 3D print fixturing stronger than 6061 AL.

Our expertise in designing and optimizing 3D models allows us to create complex geometries that are often impossible or cost-prohibitive with traditional manufacturing methods. This capability not only enhances product performance but also enables lightweighting and improved structural integrity.

Moreover, we excel in material selection and process parameter optimization, ensuring that the final product meets the highest quality standards. Whether it’s prototyping, tooling, fixturing, or end-use part production, we can adapt to various industry requirements, from aerospace to medical devices and automotive components.

Our work also supports manufacturers in reducing lead times and minimizing inventory costs by enabling on-demand production and localized manufacturing. This flexibility is crucial in today’s fast-paced market, where rapid iterations and customization are key to staying competitive.

In essence, we empower manufacturers to innovate faster, reduce costs, and achieve higher product performance, all while embracing sustainable and efficient production practices.

Contact us to learn more or request a quote today.